Stockyard Equipments Can Be Fun For Everyone

Wiki Article

8 Simple Techniques For Logistics Services

Table of ContentsWhat Does Transport And Logistics Companies Do?The Ultimate Guide To ShippingSome Known Facts About Logistics Companies.Our Logistics Companies Process PDFsSome Known Incorrect Statements About Logistics Services Unknown Facts About Stockyard Equipments

The chemical and/ or physical characteristics of some of the inbound raw products can differ commonly and these materials require homogenization to have uniform characteristics for satisfying the requirement of the processes where these materials are to be used. This homogenization operation is to be accomplished throughout the stacking as well as reclaiming of the products.The blending procedure, when put on just one product to make it uniform in attributes, is called as homogenizing operation. Considering that the mixing procedure i. e. mixing of more kind of materials or homogenization of more grade of solitary product is functionally same, just word mixing is typically utilized for both the blending as well as homogenizing procedures.

Likewise, at the very least 2 stockpiles are essential in the storage space yard, to make sure that when one stockpile is under formation, the various other created accumulation is made use of for redeeming of the product. If no blending is required, then the cone covering approach is typically selected. It needs no slewing device/ equipment in the stacker and streamlines the movement of the stacker throughout piling. logistics services.

Logistics Services for Beginners

There are three primary types of storage lawn devices which are made use of for stacking as well as reclaiming of materials. These are (i) stacker, (ii) reclaimer, and also (iii) stacker cum reclaimer.The stacker is used for preparing the accumulation with the incoming material. The machine travels on rails with the material fed to it with the backyard conveyor in between the rails - stockyard equipments. It is provided with a boom with a belt conveyor which is relocated up and down with the help of cable ropes or a hydraulic system.

The material beginning the lawn conveyor is raised by a tripper attached to the stacker and also discharged into the boom conveyor which lugs the product up to its end and also permits it to be up to develop a stockpile. The stacker takes a trip constantly to and fro to make sure that the heap is developed layer by layer.

Shipping for Dummies

The tripper car is set up in a structure suspended from the building roof covering. The traveling of the tripper auto is PLC regulated and configured to build either a cone shell or a chevron stockpile. The kind of stacker is chosen based on the stockpile format, the product residential properties, as well as the needed piling method.

The construction of a typical stacker with luffing system and different types of stackers are shown in Fig 2. The tripper as well as main body are installed on bogies to relocate the stacker on the rail track along the storage backyard.

Not known Facts About Logistics Companies Types

The luffing stacker can make stockpile in chevron and also cone covering kind of formation. The luffing and slewing stacker is used to make accumulations on both sides of the maker. Along with chevron and cone covering sort of formations (as a result of luffing ability), it can make accumulation in windrow and strata sort of formations also (as a result of the slewing capability).The chute has two legs, one for directing the product towards the boom conveyor during stacking and the various other for releasing the material in to the main chute over the impact table for bypassing the boom conveyor for straight loading to the backyard conveyor. A diverter entrance, run by an electric actuator or hydraulic cyndrical tube closes any one of the legs and permits the product to go through the other, as required.

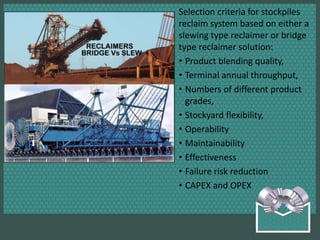

The 2 types why not check here of reclaimers which are in typical use are (i) scraper reclaimers, and (ii) bucket logistics companies hiring reclaimers. Each kind has varied designs to fit an application. In scraper reclaimers, scrape blades (toothed rectangle-shaped steel plates) are connected to 2 parallel strands of chain at routine interval. The travel of chains along with scraper blades scratches/ drags the material from the accumulation as well as discharges it on the backyard conveyor.

Not known Details About Freight Logistics Companies

The scooped material drops on the getting/ intermediate conveyor which can be bridge conveyor, boom conveyor, or barrel conveyor. The obtaining conveyor in turn discharges the product on the backyard conveyor. If there is a need for mixing then the material is scuffed/ scooped from the face/ front (whole cross area of the pile) of a heap.When material is scuffed/ scooped from the face of a pile, there is typically a harrow/ rake connected to the reclaimer which brings the material to the base, from where it is occupied by scrapes or containers. The scraper type reclaimers are lighter in weight and also are cheaper as compared to expand kind bucket wheel reclaimers.

The Main Principles Of Logistics Companies

Report this wiki page